Here is a video that I found from the first light of my first Tesla Coil. The guy in the video is my brother-in-law when he was a teenager. Enjoy…

Jeremy's Tesla Coil Place

Monday, April 18, 2011

Thursday, March 10, 2011

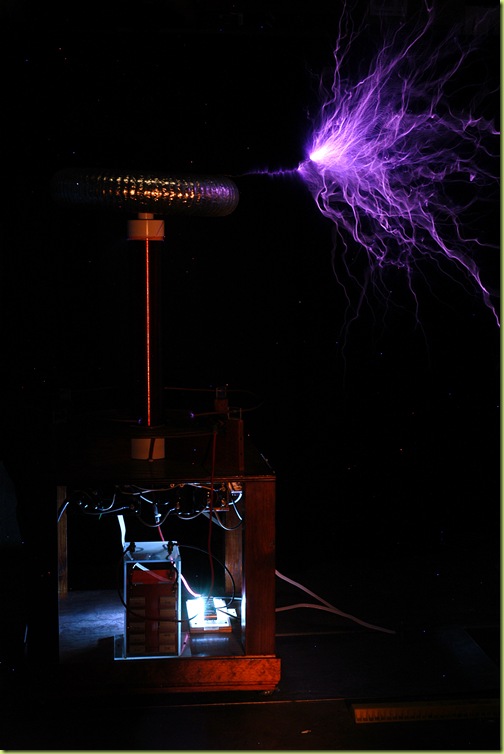

Old Spark Pictures from the Smaller Coil

Wednesday, March 9, 2011

Rotary Spark Gap Progress

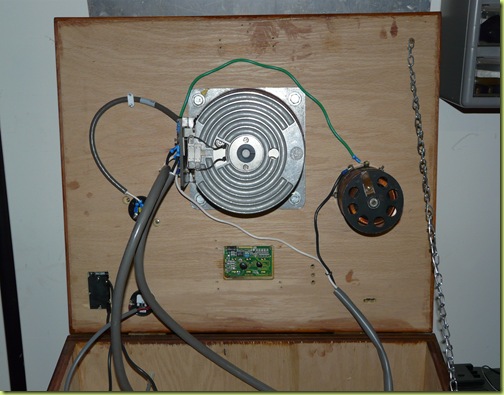

I’ve been slowly working on the rotary spark gap (RSG) trying to get it complete by the time the weather starts getting nice. I have the motor enclosure complete and hope to begin working on the actual spark gap section and the shrapnel shield (in case the pure tungsten rod shatters and spits chunks of tungsten everywhere). Below are pictures of the current progress.

Here is a top view of the motor enclosure with the hole at the top for the spark gap portion of the RSG.

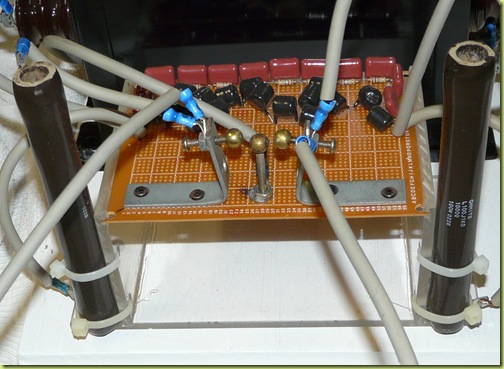

Here is the phase shifting capacitor that is connected in parallel to the input power to the motor. This is used to induce a phase shift in the motor with respect to the phase of the voltage at the NST bank. Also note the resistors placed across capacitor to bleed off any residual charge when the RSG is turned off.

Here is the fully enclosed motor for the RSG. At the top is the shaft of the motor where the spinning electrode will be connected to. The outlet on the front of the box is for the phase variable power connection (through the phase delay variac) from the control box.

Friday, February 25, 2011

Power Supply Module

Here are some pictures of the modularized power supply consisting of a bank of neon sign transformers. There are four transformers rated at 15 kV, 30 mA output each arranged in a parallel configuration to yield a 15 kV, 120 mA output. This is about 1.8 kW of power. This power supply module is very heavy and likely weighs in at close to 100 lbs. (not measured).

NST Bank, Input Power Outlet, NST Filter (Terry Filter)/Safety Gap, and Power Cable for the Rotary Spark Gap on the Bottom

Close-up of Input Power Outlet

Terry Filter and Safety Gap

New Tesla Coil Cables

Here are some pictures of the new cabling to go along with the new connections implemented for the control unit. Notice that both cables have male connectors on both cables. This was done because it is harder to find male receptacles. For safety reasons one must be sure to connect the cables to the control unit box and the tesla coil prior to connecting everything to the house wiring.

This is the cable that connects the control unit to the wall outlet.

This is the cable that connects the control unit to the tesla coil.

Friday, February 18, 2011

Tesla Coil Control Unit (TCCU) Modifications

Below is a picture of my control unit with the addition of the phase controller for the rotary spark gap. The main control switch is on the top left. Next to that is an analog voltage meter showing the output voltage going to the NST bank. The dial in the middle is the voltage control to the NST bank and the dial to the right is the RSG phase control. There is a small LCD in the middle top for future use as well as a number pad. This was envisioned to be a part of a safety/security control that was plagued with interference issues (the microcontroller reset every time the power was applied to the coil).

With the addition of the rotary spark gap to my tesla coil setup, an update to the control unit was warranted. It started with just the desire to add the phase shifter variac for the spark gap motor and turned into the inclusion of a more robust interface. I replaced the old connectors with a typical outlet for the input power and a high current appliance outlet for the tesla coil power. The outlet on the left in the photo below is for the power to the NST bank and to the RSG motor, each having separate hot and common wires. The outlet in the middle is to power the control unit. This will make for much easier connecting and disconnecting of the unit

Below is a photo of the inside of the control unit. This is the underside of the front panel.

This photo shows the power factor correction capacitor bank in the back right. Total capacitance is 195 uF which is a little shy of the ideal for my power supply (1.8 kVA NST bank). This should still aid in lowering the mains current.

Tuesday, February 8, 2011

Progress of the Rotary Spark Gap

Procured a synchronous motor made for old Teletype machines so that I can finally build a rotary spark gap. This gap offers superior quenching characteristics and a very repeatable break rate (switch closures) for reliable operation. Also the primary capacitor needs to be increased from a static gap run system when running with a rotary spark gap which will lead to increased spark length from the extra energy storage.

Currently I have the pure tungsten rods (7” long, 5/32” diameter, purchased from McMaster Carr), a bar of Delrin plastic (1” x 1” square by 12” long) that I need to cut to the correct length, and some shaft collars to hold the rod in the Delrin.

I still need to post some pictures and maybe some drawings. I’ll post those soon…